Khurja is a city located in the Bulandshahr district of Uttar Pradesh, India and just 120 kms from Delhi. It’s renowned for its pottery and ceramics industry, which has been a significant part of its economy and culture for centuries. Khurja pottery is celebrated for its exquisite craftsmanship, vibrant designs and affordable pricing. This traditional pottery has been practiced in Khurja, Uttar Pradesh, for generations, dating back to the 14th century during the Delhi Sultanate period.

The pottery is known for its distinct style, characterized by colourful glazes, intricate hand-painted designs, and durable finish. One of the distinguishing features of Khurja pottery is its use of bright colors, including blues, greens, yellows, and reds, often adorned with floral motifs, geometric patterns, or Islamic-inspired designs.

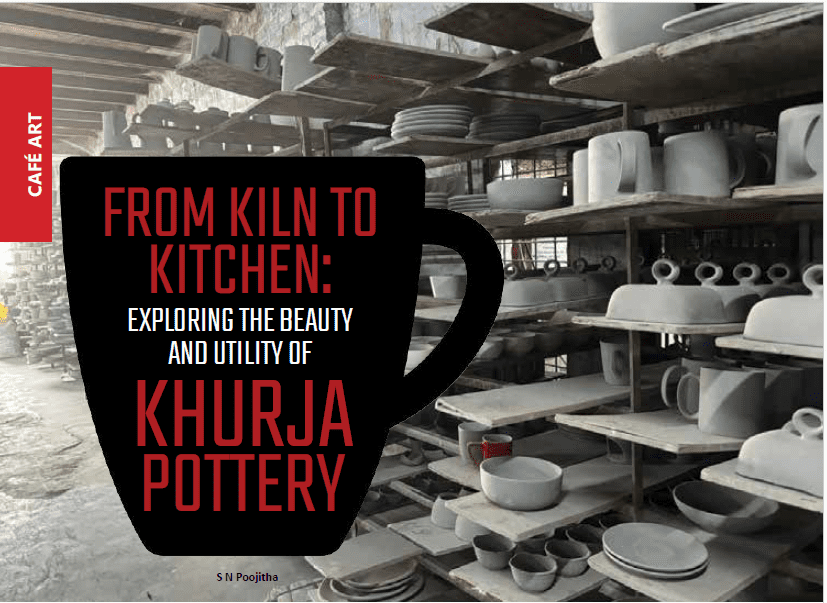

They create a wide range of pottery items, including dinnerware, vases, lamps, and decorative pieces. I had the opportunity to visit Khurja and see the making of ceramics first hand in the factories. These factories hire hundreds of laborers and artisans mostly from local area, producing hundreds ofarticles each day. The process of making ceramic tableware involves several stages, each requiring skill and precision.

1. Preparation of Clay:

The process begins with selecting the right type of clay for the desired tableware. The clay is then cleaned to remove impurities and excess moisture. It may also be mixed with other materials to achieve the desired properties, such as plasticity and strength. Each factory has a secret mixture of chemicals and soil procured from Rajasthan.

2. Forming:

There are various methods for forming ceramic tableware, including Wheel-throwing etc wherein the clay is placed on a potter’s wheel and shaped and moulded by hand while the wheel spins. This is followed by hand shaping which involves Clay slabs, coils, or pinching techniques used to shape the tableware by hand.

3. Drying:

Once formed, the tableware is left to dry partially to remove excess moisture. This stage is crucial to prevent cracking or warping during firing.

4. Trimming and Finishing:

After drying, the tableware may be trimmed to refine the shape and smooth the edges. Surface decoration, such as carving or painting, may also be applied at this stage.

5. Bisque Firing:

The partially dried tableware is fired in a kiln at a relatively low temperature (around 1650°F or 900°C) to harden the clay and prepare it for glazing. This firing process is called bisque firing.

6. Glazing:

Glaze, a mixture of minerals and water, is applied to the bisque-fired tableware to give it color, texture, and a protective coating. Glazing can be done by dipping, spraying, or brushing the tableware with glaze.

7. Decorating:

The most interesting part is the decoration, done in Khurja by hand-painting or decals (stickers), are applied to the glazed surface before the final firing. They generally use stickers or hand paint them in vibrant hues and colors and let it dry after which they are baked in gas furnaces for about 24-48hrs (depending on the sizes). Each factory operates tens of artists who intricately hand-paint the ceramics and they are led by a master painter. The master painter experiment and create design and trains junior artists to work on bulk orders.

8. Final Firing:

The glazed tableware is fired in the kiln again, this time at a higher temperature (typically around 2100°F or 1150°C), to fuse the glaze to the clay and achieve the desired finish. This final firing also strengthens the tableware and makes it food-safe.

9. Cooling and Inspection:

After firing, the tableware is allowed to cool slowly inside the kiln. Once cooled, it is inspected for any defects or imperfections before being packaged and distributed for sale. It’s quite an unique experience to see the whole process in the backend on how our crockery is made. I also learned from the factories that there are huge demand for ceramic diyas for temples especially Ayodhya.

As a matter of fact, the factory we visited mentioned that they make about 10,00,000 diyas every year. But we found that many of the factories are purely export oriented that supply all across the world. Of course Khurja visitors need not be disappointed because there are many showrooms and hundreds of small shops selling ceramic ware at affordable prices.

To sum up Khurja is a must visit for ceramic lovers, mug aficionados and those who are looking to upgrade their home decor.